Unvented Cylinders

Unvented cylinders are mains pressure hot water storage systems that provide a highly efficient way of storing and distributing domestic hot water at mains pressure throughout your home.

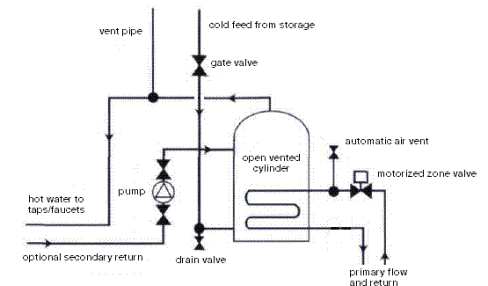

These cylinders are not open to the atmosphere, unlike open vented cylinders which are open to the atmosphere via the cylinder's vent pipe and the cylinder's cold feed pipe from the cold water storage cistern/tank.

These mains pressure cylinders provide quicker heat recovery than the low pressure open vented cylinder, i.e, it takes less time to heat up.

Because water is supplied from the mains supply and not from a cold water storage cistern/tank, the flow rate and water pressure from a unvented cylinder at the outlets (taps/faucets shower heads) is much greater than from the storage fed open vented cylinder.

Below is a list of what's on this page:

System Controls

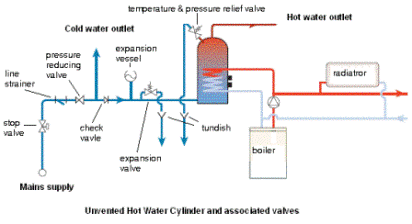

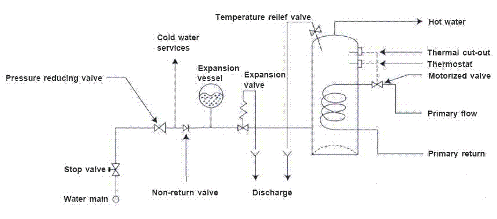

Unvented hot water storage cylinders, unlike open vented cylinders, require a number of safety devices to ensure the safe operation of the system.

Because the unvented cylinder is 'sealed from the atmosphere', the hot water temperature, water expansion and water pressure have to be monitored and accommodated (taken up safely) in normal operation, and, in the event of a problem, be capable of discharging any excess pressure and hot water safely.

The above picture shows an unvented cylinder and control devices

The picture below shows an open vented cylinder system

Below are the 'Three Tier' safety control devices for unvented hot water cylinders:

- 1 A cylinder thermostat set at about 60 - 65ᵒC

- 2 A cylinder high temperature energy cut-out thermostat set to operate around 80 - 85ᵒC

- The high temperature energy cut-out thermostat, cuts off the heat source by shutting off the boiler and closing off the 2 or 3 port motorized valves, or by cutting off an electric immersion heater. The high temperature energy cut-out device is non self-resetting, i.e, you have to manually reset it therefore alerting you of a problem

- 3 A cylinder temperature and pressure relief valve set to operate around 90 - 95ᵒC and pressure relief set around 6 - 8 bar (600 - 800 Kpa)

- Discharge pipework from both the temperature/pressure relief and expansion relief valves is run via an internal tundish (air gap) to a safe discharge point. This pipework must be metal and not plastic due to possible high water temperatures.

- The tundish provides an air gap in the discharge pipe so you can be visually alerted to any problems and also to provide an alternative (albeit messy) escape route for the water if the discharge pipe freezes

- An expansion relief valve for discharging water if the expansion vessel or pressure reducing or limiting valve fails, this is set around 6 bar (600 Kpa). No other valve must be fitted between this relief valve and the cylinder

- An expansion vessel to take up the expanded hot water. With some unvented cylinders the expansion vessel is an air pocket within the internal chamber of the cylinder, this is commonly called a 'bubble top'

- Some countries don't use expansion vessels and purely rely on a cold water expansion valve that opens and discharges the expanded water to a drain. Expansion vessels prevent this wastage of water

- A non-return/check valve to prevent backflow of hot water to the cold domestic/residential and mains supply

- A pressure reducing or limiting valve to maintain the system's required operating pressure

- A line strainer to prevent any form of solid matter entering the system and causing valve obstruction

A composite or combination valve contains the pressure reducing valve, line strainer,expansion valve and check valve designed to speed up installation.

Some composite valves also have an isolating valve and a connection branch for balanced cold water supply.

A balanced system is one in which both the hot and cold water is distributed at equal pressure.

Note: The cylinder thermostat, the high temperature energy cut-out thermostat, the temperature and pressure relief valve is a three tier level safety protection system designed to prevent overheating and over-pressurization in the unvented cylinder which could lead to an explosion.

The pressure reducing or limiting valve also prevents over-pressurization of the system.

If any of the above controls are faulty do not attempt to repair them. They must be replaced by a qualified installer or the unit returned to the manufacturer for repair.

Note: Water at sea level will boil at 100ᵒC, but water that is sealed from the atmosphere will remain in a liquid state at temperatures far higher than 100ᵒC. If this heated water which is under pressure was suddenly exposed to the atmosphere the result would be a flash explosion as the water is transformed into gas (steam) increasing in volume by 1600 times.

The controls for a domestic/residential unvented cylinder is designed to prevent temperatures reaching and exceeding 100ᵒC.

Operating Pressure

The domestic/residential unvented cylinder will operate in a pressure range of 2 bar to 3.5 bar (200 - 350 Kpa). Before the installation of an unvented cylinder, you will need to establish whether your mains supply can provide adequate pressure and flow rate.

For typical domestic systems a minimum pressure of 1.5 bar (150 Kpa) and 20 litres/min water flow rate is required.

If the water pressure is too low to meet the required operating pressure for the unvented cylinder then water can be fed from a low level cold water storage cistern/tank. This cistern/tank is mains fed and water is drawn from it by a pumping unit that supplies the hot and cold system at the pressure required.

|

Got any good plumbing tips? |

Material Types

The material that the cylinder is made from will have a direct bearing on the inlet pressure that the system is required to operate at.

Unvented cylinders are primarily made from 3 material types:

- Copper cylinders are made to withstand pressures up to 4.5 bar (450 Kpa) and an operating pressure around 2 bar (200 Kpa)

- Low-Carbon Steel cylinders are made to withstand pressures up to 6 bar (600 Kpa) with an operating pressure of 3 - 3.5 bar (300 - 350 Kpa). Steel cylinders however, need to be corrosion protected. This can be with a vitreous enamel, a cement-sand or plastic lining

- Stainless Steel cylinders can withstand pressures up to 10 bar (1000 Kpa) with an operating pressure of 3 - 3.5 bar (300 - 350 Kpa)

In earlier models of light gauge copper unvented cylinders a vacuum relief, or anti vacuum valve, was sometimes fitted to prevent possible implosion. This could happen when draining the cylinder without venting the system, e.g, by not opening a tap/faucet, or where water is drawn off faster than it can be replaced, e.g, a fall in mains pressure, or if the cylinder was cooling after the water supply was closed off.

Direct or Indirectly Heated Cylinders

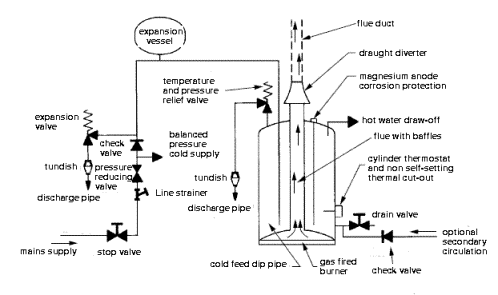

An unvented cylinder can be directly heated by electric immersion heaters, or a gas burner, or indirectly heated by a central heating boiler through the primary heat exchanger (the coil inside the cylinder).

Note: The combination primary storage unit (CPSU) is a combination boiler with an 80 litre built in unvented hot water storage vessel. See Home Heating Boilers.

The picture above shows a directly heated gas fired unvented cylinder

The picture below shows an indirectly heated unvented cylinder

Unit or Package

Unvented cylinders can be supplied from the manufacturer in two ways, as a unit, or as a package.

A 'Unit' means the unvented cylinder is factory fitted with all the safety devices and cold water operation (function) devices by the manufacturer, which are:

- Line strainer

- Pressure reducing or limiting valve

- Non-return/Check valve

- Expansion vessel

- Expansion valve

- Tundish

- Temperature and pressure relief valve

- High temperature energy cut-out thermostat

- Motorized valve for indirect heated cylinders

Note: If the unit is to be heated indirectly from a boiler then the high energy cut-out may be on the boiler.

With the 'Package', only the temperature and pressure relief valve and high temperature energy cut-out thermostat is factory fitted by the manufacturer, the other devices will be fitted on site by the installer.

Advantages

|

There are a number of advantages with using an unvented hot water cylinder. For example:

- High water pressure - great for showers so no need for booster pumps

- Balanced water pressure at hot and cold taps/faucets

- Balanced shower pressure - allowing for safer temperature control

- Better high pressure terminal fittings - such as taps/faucets and valves

- No cold water storage cistern/tank - enabling loft conversion

- Improved cylinder location flexibility due to mains water pressure

- Quicker to install than an open vented cylinder and its associated fittings

Disadvantages

The disadvantages with unvented cylinders are:

- With low mains water pressure and poor flow rate, the system may be unable to operate

- No water storage in the event of a water mains failure

- Extra controls occupy more space (unless using a composite/combination valve)

- Price - unvented cylinders usually cost more than open vented cylinders

Home Heat Loss Heat Gain Radiant Heat Central Heating Radiators UFH

Heat Pumps GSHP's WSHP's ASHP's Solar Heating PV Systems Boilers

Water Heaters Insulation Elec-Heaters

Terms of Use | Privacy | Contact Us

|

Visitors Say

Hi, My name is Shannon and I'm one of home-heating-systems-and-solutions.com readers. I'd like to thank you for the excellent information I've found on home-heating-systems-and-solutions.com, it's one of my favorite readings on the net. Warmest Regards Shannon United States

Thanks for the advice for removing an air lock from an indirect system. Had to change an inlet on my cistern. First time I have tried any home plumbing. After draining the cold tank system air locked when I refilled the tank. Garden hose and mains pressure up the tap sorted my problems. Would not have known what to do without the advice on the site. Many thanks Sean United Kingdom.

An excellent site. I have found it very usefull. I am currently in the design phase of a new house and have be pondering which heat system to use. From your site I have been able to choose the right system. Ross New Zealand

I enjoyed your site. Pat United States

We're so excited to announce our first Children Book

The Special and Talented Dog Show

To order click here

The second book published is called

Flying Things

This is aimed at a pre-school audience and is a rhyming story. You can buy by clicking here

To read more about our children's books, click here

|

Visitors Say

Hi, My name is Shannon and I'm one of home-heating-systems-and-solutions.com readers. I'd like to thank you for the excellent information I've found on home-heating-systems-and-solutions.com, it's one of my favorite readings on the net. Warmest Regards Shannon United States

Thanks for the advice for removing an air lock from an indirect system. Had to change an inlet on my cistern. First time I have tried any home plumbing. After draining the cold tank system air locked when I refilled the tank. Garden hose and mains pressure up the tap sorted my problems. Would not have known what to do without the advice on the site. Many thanks Sean United Kingdom.

An excellent site. I have found it very usefull. I am currently in the design phase of a new house and have be pondering which heat system to use. From your site I have been able to choose the right system. Ross New Zealand

I enjoyed your site. Pat United States

We're so excited to announce our first Children Book

The Special and Talented Dog Show

To order click here

The second book published is called

Flying Things

This is aimed at a pre-school audience and is a rhyming story. You can buy by clicking here

To read more about our children's books, click here